PRECISION HEAT, RELIABLE PERFORMANCE

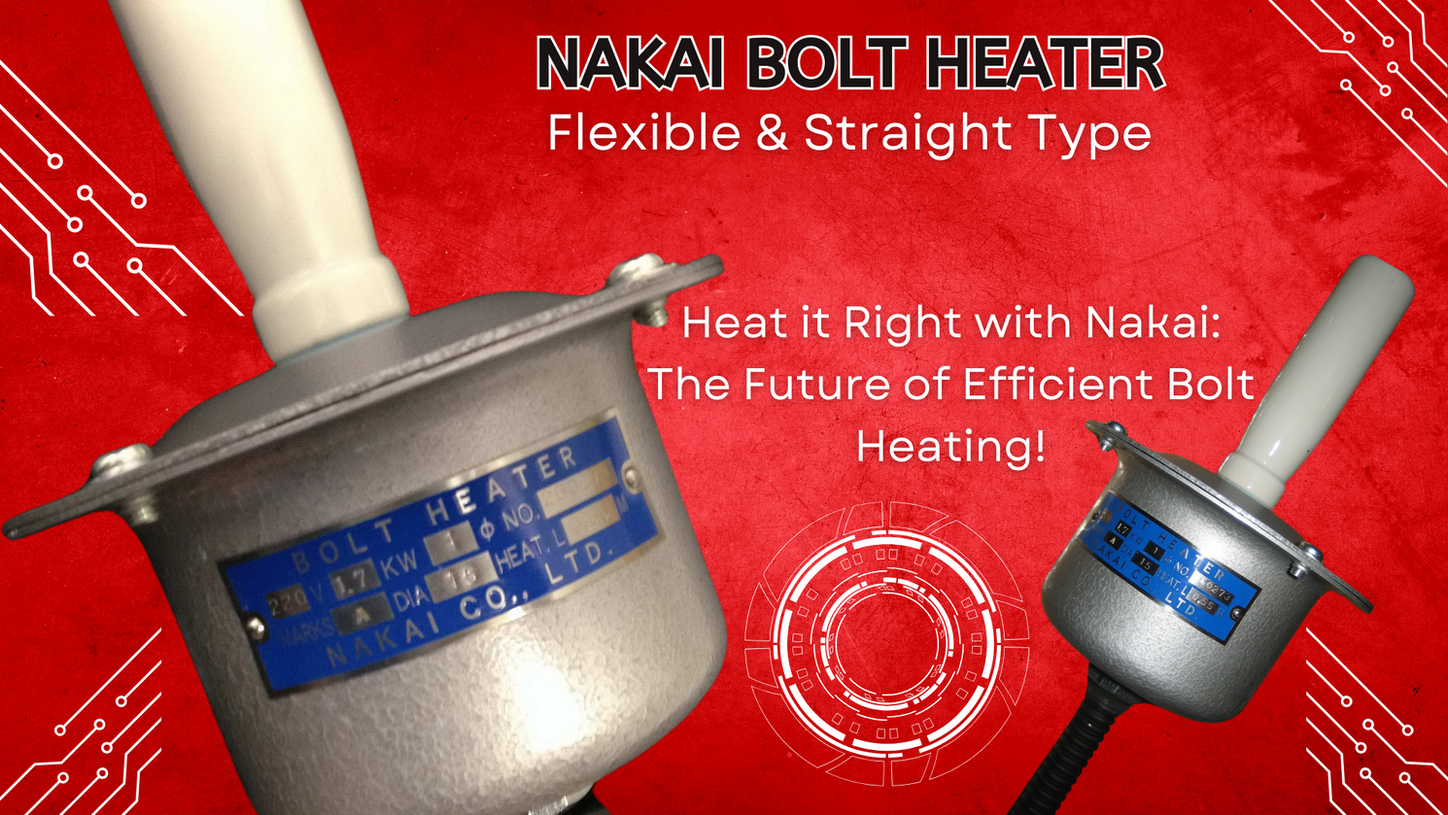

Nakai Bolt Heater Flexible & Straight Models by Nichiboku Ltd

Key Features and Benefits of Nakai Bolt Heaters

Key Features and Benefits of Nakai Bolt Heaters

Nakai Bolt Heater Use:

1. The Nakai Bolt Heater is an innovative industrial tool specifically crafted for the efficient tightening and loosening of bolts found in turbines and compressors.

2. It significantly surpasses traditional methods in terms of safety, ensuring a higher level of protection for users.

3. The tool is a time and labor saver, streamlining processes that traditionally took much longer to complete.

4. It employs induction heating technology to provide fast, accurate, and localized heating. This is achieved by inserting a stik bar directly into the bolt.

5. The heater produces a precise amount of heat, causing the bolt to expand to a specific length. This expansion facilitates the process of tightening or removing the nut bolt, making the task easier for operators.

The Nakai Bolt Heaters are expertly engineered for the preheating of bolts or studs across a diverse range of diameters. These sophisticated devices are integral in the assembly or servicing of hydraulic presses, turbines, and similar machinery, where intense heat application is essential for the expansion of components. This process facilitates the precise tightening of tie rods using specialized tools. Upon cooling, the components undergo contraction, thereby enhancing the tightening effect on the nuts for increased stability.

The Nakai Bolt Heater portfolio encompasses two distinct models: the "Flexible" and the "Straight" variants. Both configurations are characterized by a fully encased heating element, inclusive of a terminal box and clamping mechanism, complemented by a handle insulated with high-grade ceramic material for enhanced safety and durability.

.png)

Flexible Type Bolt Heater

The Nakai Bolt Heaters, available in Flexible type, specialized tools designed for specific applications in industrial settings. Unique features and uses, catering to different requirements in the assembly and maintenance of machinery.

-

Design: The Flexible Nakai Bolt Heater is characterized by its adaptable design. It consists of a heating element that can be bent or flexed, allowing it to fit into tight or irregular spaces.

-

Applications:

-

Complex Assemblies: Ideal for heating bolts or studs in areas with limited access or where components are not aligned in a straight line.

-

Variable Geometries: Useful in situations where the bolt or stud configuration varies significantly, requiring a more adaptable heating approach.

-

-

Advantages:

-

Versatility: Can be used in a variety of settings and configurations.

-

Ease of Use: Its flexible nature allows for easy maneuverability and positioning

-

At Nakai Bolt Heater, our commitment is to engineer solutions that precisely align with the technical specifications required by our clients to achieve their operational goals.

Our product range is tailored to meet diverse process needs, offering a spectrum of technical variations in terms of Capacity (Kw), Electrical Power (V), Diameter Options (D), Overall Length (L), Active Heating Zone (H), and Non-Heating Zone (NH).

Specifically, within our Flexible Nakai Bolt Heater series, we cater to a range of Standard Diameters (D), including but not limited to: 15mm, 17.5mm, 19mm, 20mm, 23.5mm, and 26mm.

Standard Specification Details: Enhanced with Advanced Connectivity and Compliance Features"

-

Cable Configuration: Equipped with a 2-meter long 2PNCT 3C 2MM² cable, providing robust and reliable electrical connectivity.

-

Plug Options: Fitted with a standard American male plug, with the option to include a male & female plug configuration for versatile connectivity.

-

Compliance Documentation: Each unit includes a comprehensive Inspection Report, ensuring adherence to quality and safety standards.

We are fully prepared to accommodate unique technical requirements beyond our standard specifications. Should you have any bespoke specifications, we encourage you to reach out. Our team is dedicated to providing prompt and comprehensive responses to tailor our solutions to your specific needs.

Straight Type Bolt Heater

The Nakai Bolt Heaters, available in Flexible type, specialized tools designed for specific applications in industrial settings. Unique features and uses, catering to different requirements in the assembly and maintenance of machinery.

-

Design: The Straight Nakai Bolt Heater features a rigid, straight heating element. This design is more traditional and is suited for standard applications.

-

Applications:

-

Standard Assemblies: Perfect for heating bolts or studs in straightforward, accessible areas.

-

Uniform Geometries: Effective in environments where the bolt or stud arrangement is uniform and linear.

-

-

Advantages:

-

Efficiency: Provides quick and even heating for standard bolt sizes and configurations.

-

Simplicity: Its straightforward design makes it easy to use, especially in repetitive or standardized tasks.

-

At Nakai Bolt Heater, our mission is to engineer solutions that meticulously cater to the specific technical requirements essential for our clients' operational success.

Our product portfolio is designed to address a wide array of process demands, offering a diverse range of technical specifications in terms of Heating Capacity (Kw), Electrical Power Rating (V), Diameter Options (D), Overall Length (L), Active Heating Zone (H), and Non-Heating Zone (NH).

For our Nakai Bolt Heater (Standard - Rigid) series, we provide an assortment of Standard Diameters (SD), including but not limited to: 9.5mm, 15.3mm, 18mm, 19mm, 20mm, 24mm, and 26mm.

Standard Specification Details: Enhanced with Advanced Connectivity and Compliance Features"

-

Cable Configuration: Equipped with a 2-meter long 2PNCT 3C 2MM² cable, providing robust and reliable electrical connectivity.

-

Plug Options: Fitted with a standard American male plug, with the option to include a male & female plug configuration for versatile connectivity.

-

Compliance Documentation: Each unit includes a comprehensive Inspection Report, ensuring adherence to quality and safety standards.

We are committed to accommodating bespoke technical requirements beyond our standard offerings. Should you require specifications tailored to your unique needs, we invite you to contact us. Our team is dedicated to delivering prompt and detailed solutions, ensuring alignment with your specific operational objectives.

Ensuring Safe Delivery: Our Premium Packaging Standards for Nakai Bolt Heaters

Post-Packaging Inspection: Before dispatch, each packaged unit undergoes a rigorous inspection by our quality assurance team to certify its condition and readiness for shipment.

Through these meticulous packaging practices, we ensure that every Nakai Bolt Heater is delivered to its destination in optimal condition, reflecting our commitment to quality, safety, and customer satisfaction.

At our facility, we emphasize professional and safe packaging services to ensure that each Nakai Bolt Heater is delivered without any inconvenience.

Key Packaging Features:

-

Advanced Materials: We use high-grade, impact-resistant materials for robust protection against physical impacts, vibration, and environmental factors.

-

Custom-Fit Enclosures: Each heater is encased in a custom-fitted protective enclosure, minimizing movement and potential damage during transit.

-

Secure Sealing and Cushioning: Airtight sealing and superior cushioning materials are used to protect against shocks and vibrations.

-

Compliance with Standards: Our packaging adheres to international shipping standards, ensuring safe and smooth delivery.

-

Clear Labeling and Documentation: Packages are clearly labeled with handling instructions and product details, accompanied by comprehensive documentation for easy tracking.

-

Quality Inspection: Each package undergoes a thorough inspection before dispatch to ensure it meets our high standards of quality and safety.

-

Through these efficient and meticulous packaging practices, we guarantee the safe and timely delivery of every Nakai Bolt Heater.

.png)