Ameroid UB Type Oil-Water Separator – High-Performance Industrial Separator

- Luis Alberto Fing

- Oct 10, 2025

- 3 min read

Welcome to Nichiboku's industrial Blog

Introduction to Ameroid UB Type Oil-Water Separator

In factory production lines and industrial processes, fine oil and sludge in water-based liquids such as coolants, cleaning fluids, and wastewater can degrade performance, shorten fluid life, and complicate environmental compliance.The Ameroid UB Type Oil-Water Separator is a reliable, heavy-duty 2-in-1 solution designed to separate oil from water and remove sludge simultaneously.

This article professionally outlines its features, applications, selection points, benefits, and how to get started.

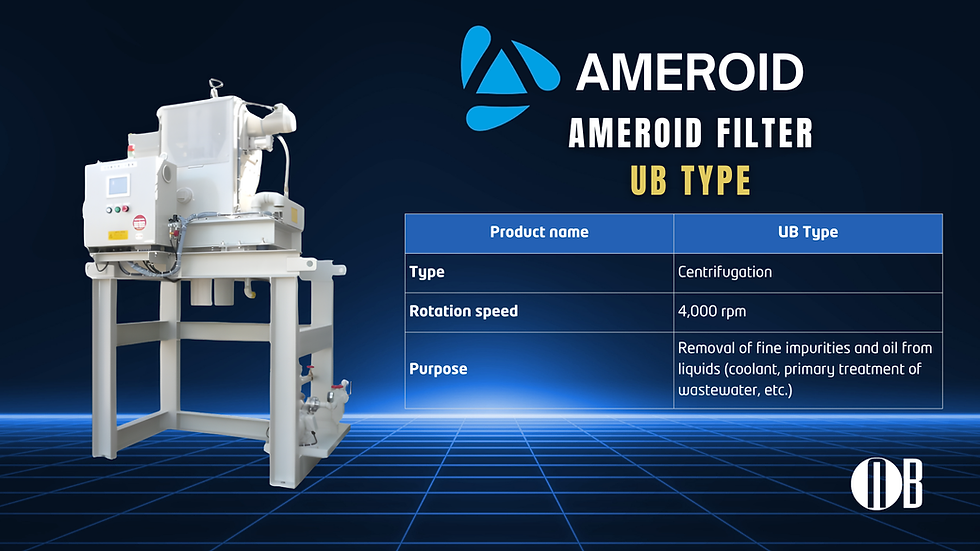

Ameroid UB Type Oil-Water Separator: Product Overview and Features

Product Summary

The Ameroid UB Type Oil-Water Separator separates oil and sludge from oil-contaminated water-based solutions.

Oil is continuously discharged from the oil outlet

Sludge is solidified and discharged periodically from the sludge outlet

Flow capacity ranges: approximately 1,000 L/h to 3,600 L/h

Compatible fluids: Cleaning liquids, degreasing fluids, water-soluble coolants, machining fluids, wastewater

Key Features

Feature | Description |

Wide Fluid Compatibility | Removes oil and impurities from various aqueous solutions regardless of oil type |

Handles Cloudy Solutions | Efficient oil-water separation even in murky liquids |

Sludge Solidification and Discharge | Manual or fully automatic sludge discharge options available |

Multiple Size Options | Available in compact to large-capacity models |

High Centrifugal Force | Up to 1,800G–3,200G |

Filter-Free Design | Reduces consumables and lowers maintenance costs |

Model Specifications

Model | Sludge Treatment | Max Flow Rate | Main Motor | Max G-Force | Weight |

UB-H1 | Manual | ~15 L/min | 1.5 kW | ~1,800G | ~200 kg |

UB-S2 | Fully Automatic | ~30 L/min | 3.7 kW | ~3,200G | ~700 kg |

UB-S4 | Fully Automatic | ~60 L/min | 5.5 kW | ~1,800G | ~1,000 kg |

(*Note: Flow rate depends on fluid characteristics, oil concentration, and particle sizes.)

Applications and Benefits of Ameroid UB Type Oil-Water Separator

Ideal Applications

Purification of cleaning/degreasing fluids

Coolant oil removal

Fluid life extension in machining operations

Primary wastewater treatment

Widely used in automotive, metal processing, electronics, and food industries

Key Benefits

Extended fluid life – reduced contamination buildup

Improved product quality – clean process fluids maintain performance

Environmental compliance – reduces oil content in effluents

Cost savings – no filters and less fluid waste

Compact yet powerful – handles large capacity in limited space

How to Select the Right Ameroid UB Type Oil-Water Separator

When selecting the Ameroid UB Type Oil-Water Separator, consider:

Fluid Characteristics

Oil type (cutting, lubricating, cleaning, rust-preventive, etc.)

Oil concentration and particle size distribution

Required Flow Rate

Peak and average flow rate in L/min or L/h

Sludge Removal Type

Manual or fully automatic

Installation Space

Equipment dimensions, height clearance

Maintenance Requirements

Access to service parts, cleaning procedures

Automation & Control Needs

Continuous monitoring, alerts, system integration

Proper evaluation of these factors ensures optimal performance and ROI.

Case Study: Ameroid UB Type Oil-Water Separator in Action

A metalworking factory had trouble with coolant contamination due to residual oil and sludge. Frequent fluid replacement led to high operating costs.

Solution: The plant installed the UB-S2 model, resulting in:

Tripled coolant lifespan

Lower oil concentration in effluent

Reduced labor for maintenance

Stabilized machining quality

ROI was achieved quickly, and long-term savings were substantial.

Implementation Process for Ameroid UB Type Oil-Water Separator

Consultation & Fluid Analysis

Review of your current fluid system and contamination type

Model Selection

Choose between UB-H1, UB-S2, UB-S4 based on requirements

Quotation & Specification Proposal

Includes power supply, pump configuration, control panel specs

Installation & Test Run

On-site support for commissioning and optimization

Ongoing Support

Maintenance plans, parts supply, and operational training NB- AMEROID section page:

Enhance System Cleanliness with Nichiboku Ltd.

At Nichiboku Industrial, we provide advanced filtration solutions, including Ameroid FL Type filters for flushing applications. Contact us today to improve your system’s cleanliness and reliability with our trusted industrial products.

.png)

Comments